I'm building a car and would like to hear about folks's oil tank/engine/catch tank venting.

My car has the original oil tank (Ralt RT-4) with two breather ports. One looks to be for vapors entering the oil tank and one for exiting (that's my hunch based on the baffling I can see).

My engine (Suzuki GSXR Gen 2) has a breather port in the back of the engine. I think it was where the reed valves were. Now it has a -8AN fitting.

I'm assuming I should run a hose from that port to my oil tank, then use the other port to the catch can.

Sounds simple, but I've heard two things that make me think about other options:

1. A buddy with a similar layout took his newly built car out and it pushed a lot of oil into the catch can. We've had a dozen theories about the cause, but no definite known cause. He's made several changes and will test them in a few weeks.

2. I've heard that George Dean has suggested using the clutch cover's oil filler cap as a vent (return line?), and perhaps some of the oil/vapors coming out of the oil tank can be persuaded into returning to the engine, rather than to the catch can.

I kind of like that idea, but I'm not sure about where the high and low pressures are. For instance, piston ring blowby might cause the crankcase to be pressurized, but the sump pumps might be sucking enough to cause a vacuum.

Regardless, the oil tank will need to vent that pressure, so there will definitely be vapors/vents leaving the oil tank. It would be great if the line from the oil tank to the catch can could have a tee or something to encourage vented oil back into the engine. I thought about using the oil fill port for that, but with a spinning clutch plates, will oil be slung out, making that a bad place for a return line?

Hope all that makes sense, and I know I'm probably overthinking it, but I want to understand the flow of the oil/vapors. Plus, I figured many of you have similar cars with vent plumbing that works great.

Thanks, guys.

Reply With Quote

Reply With Quote

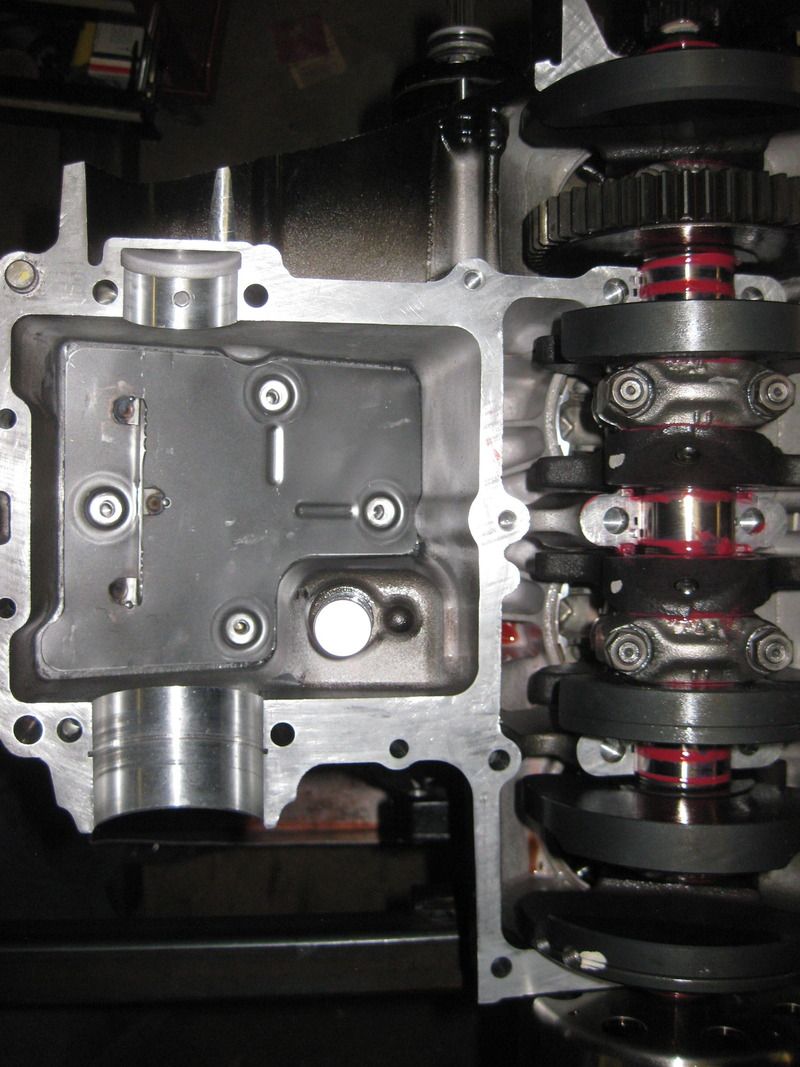

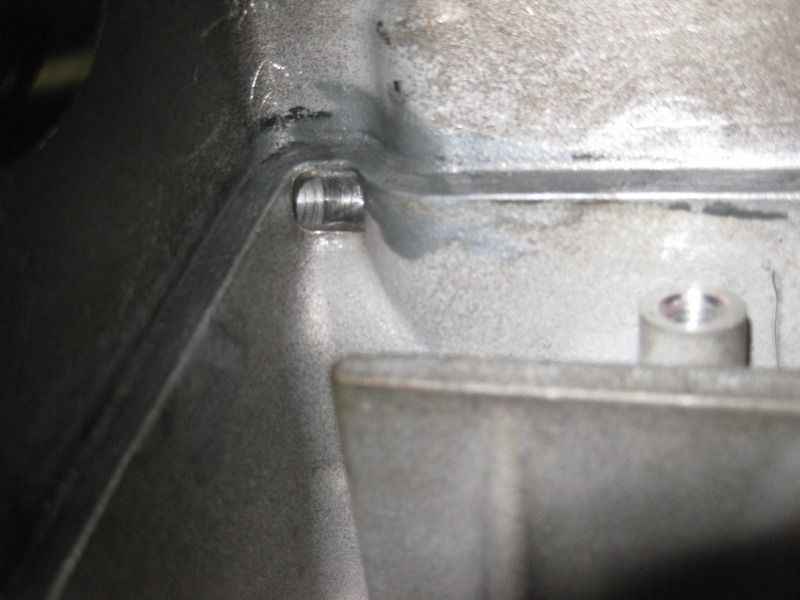

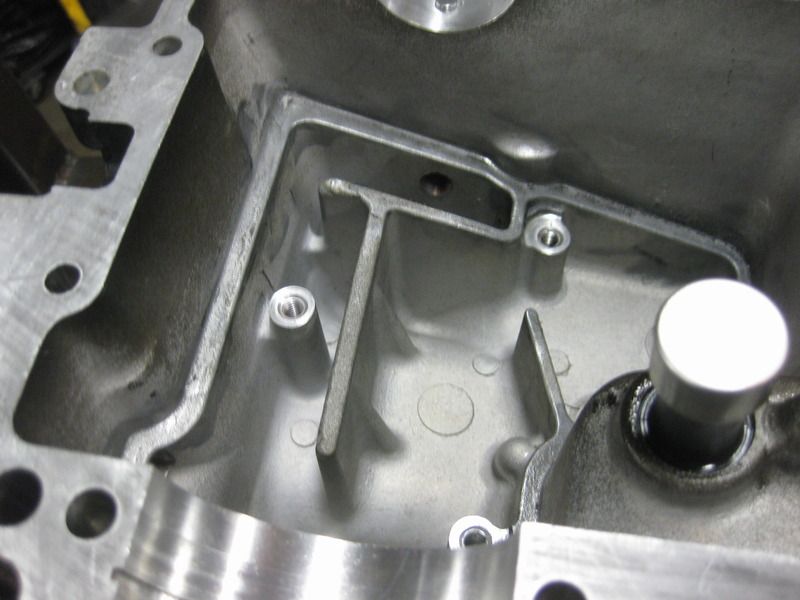

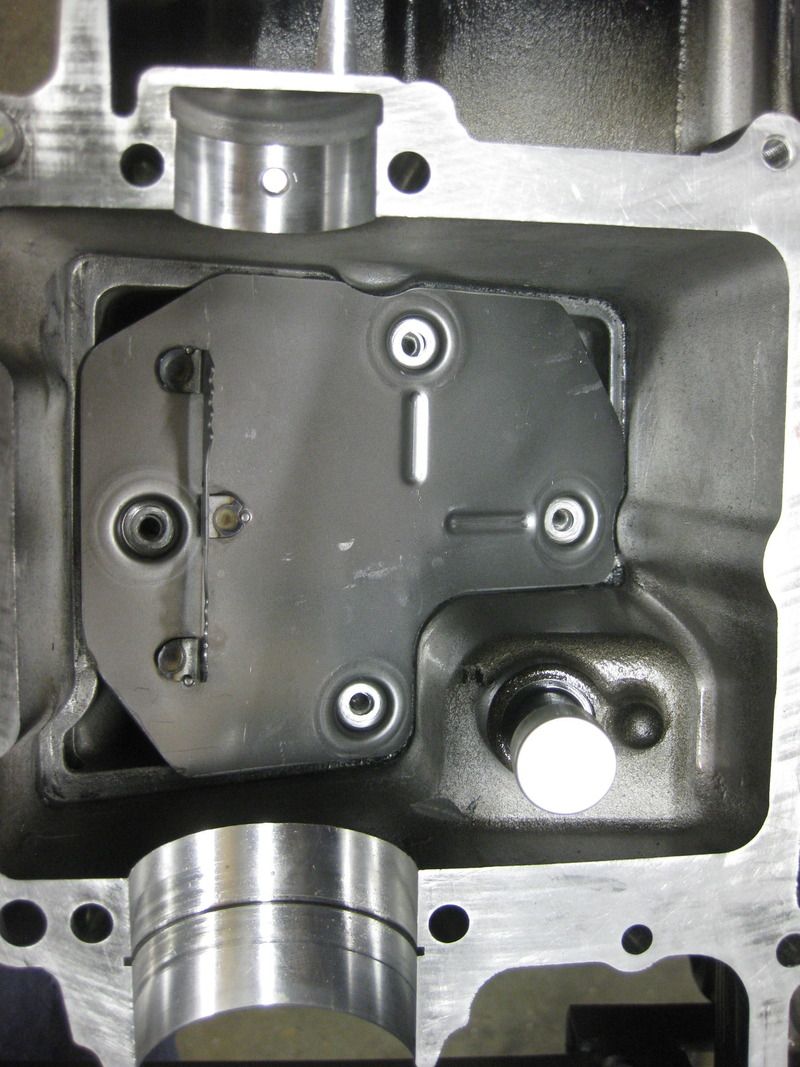

After removing this cover which is a challenge the way Kawasaki has glued it in place with there super rtv bond there is a chamber with 2 8mm inlet holes;

After removing this cover which is a challenge the way Kawasaki has glued it in place with there super rtv bond there is a chamber with 2 8mm inlet holes;

The result has been no oil in the catch tank and I was able to reduce the amount of oil in the engine by about 1/2 a quart.

The result has been no oil in the catch tank and I was able to reduce the amount of oil in the engine by about 1/2 a quart.