I have a 1984 Reynard and I have some overheating issue on my car.

I ran my car on the track for about 5-7min. and the reserve bottle is full of water and it's bubbling a lot. Each time we bleeded it and added some water and it's still the same.

So far here's what we know:

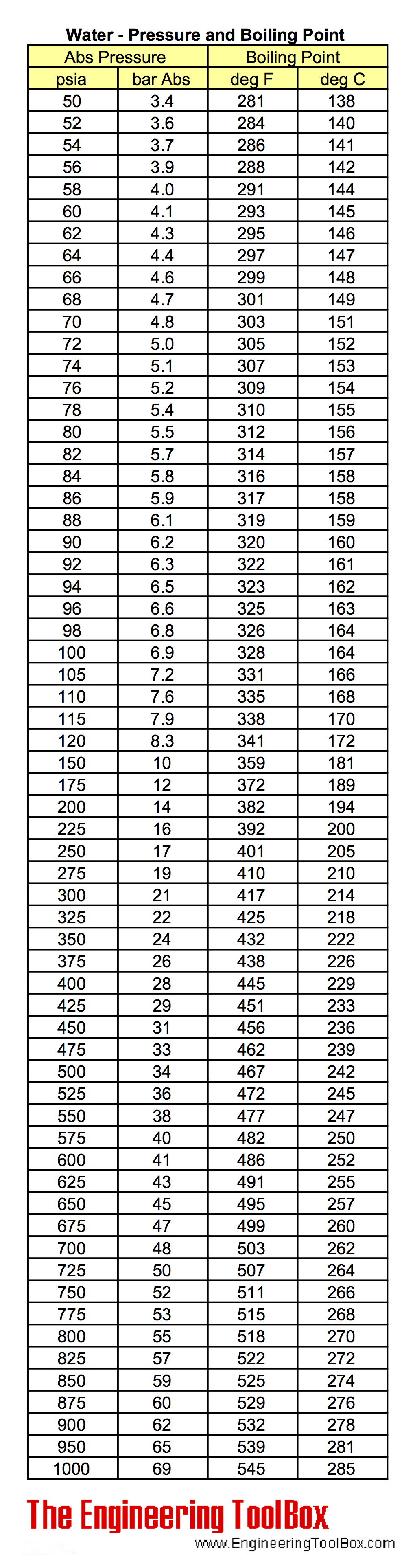

- The sytem is holding 14psi for over 45 min. and there's no leak.

- I removed the water pump and everything looks fine.

- We blew air trought the radiators and it's circulating properly.

- The sparkplugs looks pretty good.

- The timing is fine but maybe we can play with that a bit.

Any idea

Reply With Quote

Reply With Quote

)

)

Hot tamales!

Hot tamales!

On the cool down lap ( it got down to 105 C) I smelled coolant. HUH OH. When I got to impound I saw a pinhole leak in one of the main hoses, where it tore against a clamp as it must have strained at nearly 24psi.

On the cool down lap ( it got down to 105 C) I smelled coolant. HUH OH. When I got to impound I saw a pinhole leak in one of the main hoses, where it tore against a clamp as it must have strained at nearly 24psi. But I had a broken shifter a few races back and over-reved the snot out of it, that might have bent #3 exhaust.

But I had a broken shifter a few races back and over-reved the snot out of it, that might have bent #3 exhaust.  The heat might have not helped the cylinder walls... or the valve seats... or...

The heat might have not helped the cylinder walls... or the valve seats... or...