Hi Guys,

I used to post on here more, but I have started a business, had a couple kids, building a house, etc. Fortunately my wife is still letting me play with race cars, and I recently sold my FC and upgraded to P2.

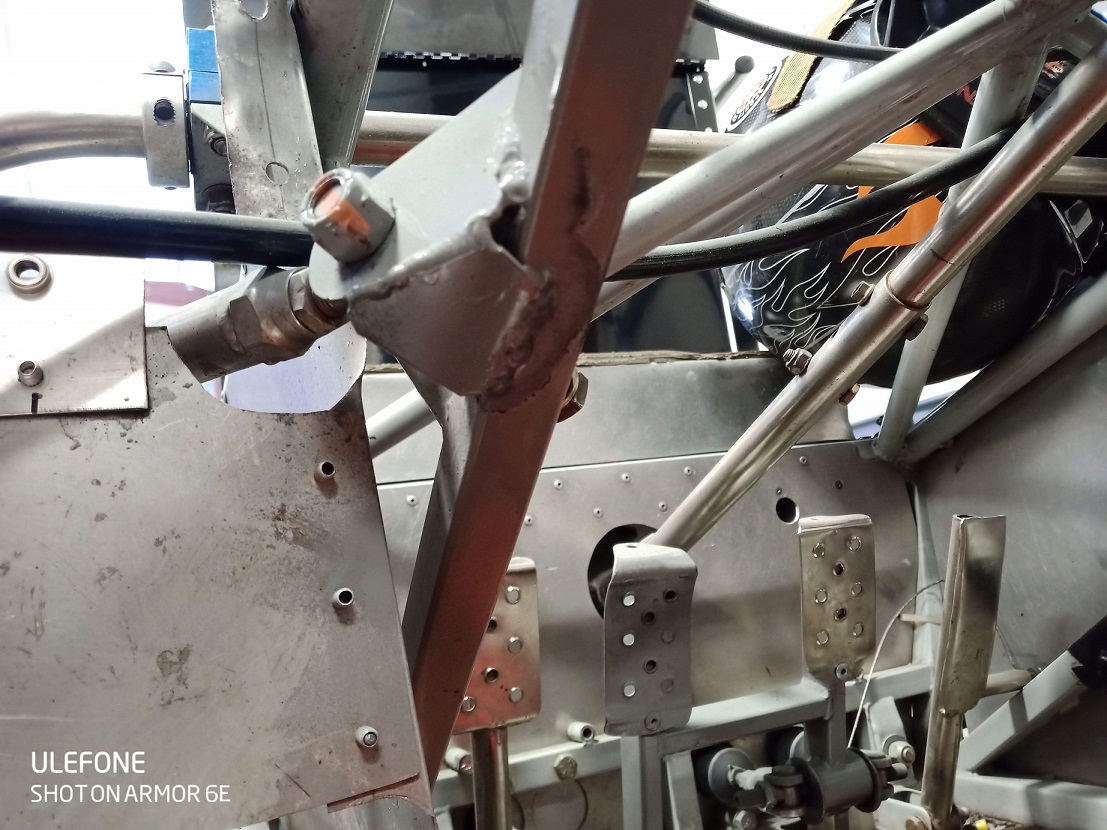

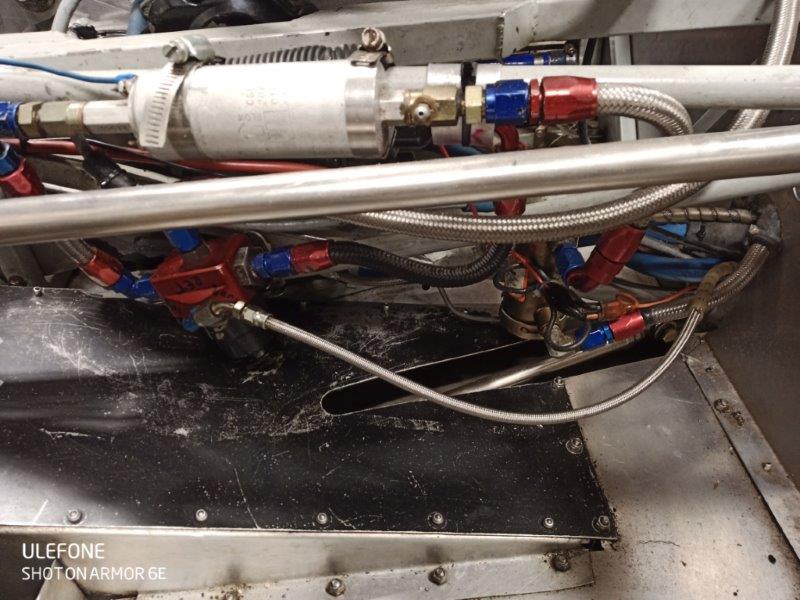

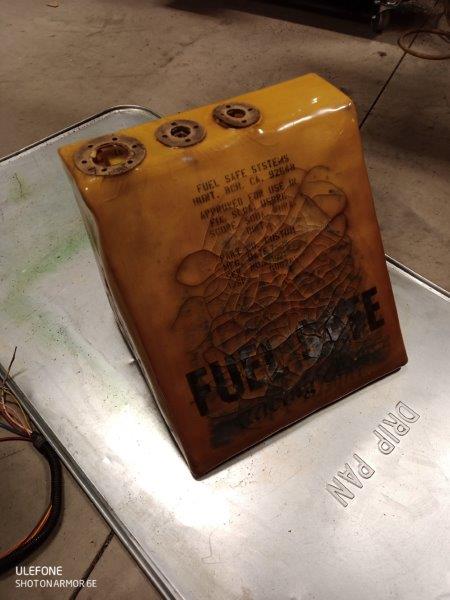

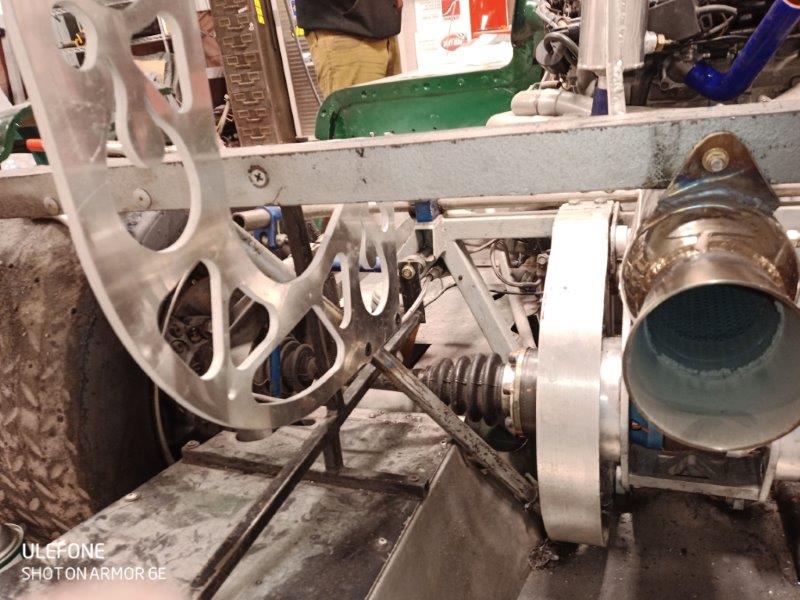

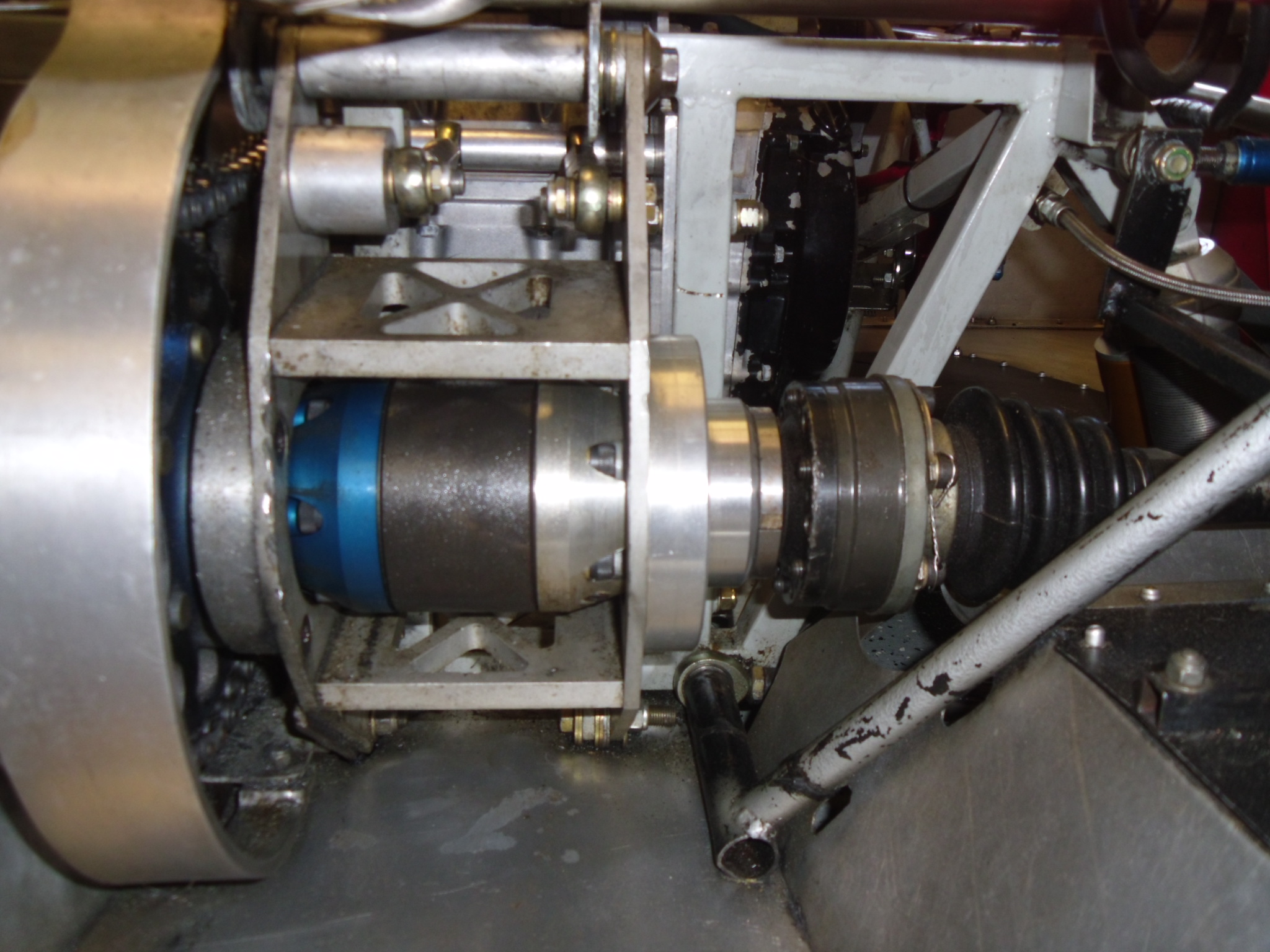

The new car is a '98 AMAC AM-7, which I think most people consider kind of dated for P2, but I like the car and I think with a few tweaks it can still be competitive. So I figured I might as well document the build for your entertainment. Feel free to comment!

Here is the car as received:

More to come.....

Reply With Quote

Reply With Quote