Ill be checking data soon to see how long the delay was/is in my car.

Ill be checking data soon to see how long the delay was/is in my car.

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

Loaded up RA/Sprints race data. Intresting stuff.

I think we are starving the engine of oil.

Under braking for corner 1 (of best lap, 240 oil, 188 water) from 149mph to 102mph (10K RPM), oil psi drops to 28 psi around 118mph (1 second into braking). At 105mph (.5 second later), its on its way back up and only 0.2% throttle. By the time I pick up the gas (another .5 second) oil psi is already 54 psi. 1.3 seconds later I'm at 100% throttle and have been at peak oil psi for over a second.

That is the problem. Just like I was thinking before in previous post, pump is turning, braking or not, should be making oil psi regardless especially at 10,000 rpm.

Thinking of pinning the front door closed in pan and/or covering those drain back holes up front and possibly a scoop to catch oil as it goes forward and directs it into sump section.

Hmmmm.

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

I went back through all my data after we talked Jake and I have 0 (zero) traces that show full throttle after braking without the oil pressures immediately coming back up. This is two years worth of 07/08 GSXR data from over 50 different sessions. As I told you too I run with the oil 3/4 to all the way up the sight glass and have ran tracks with both long left handers and right handers without issue. Putting more oil in the sump than up the sight glass 3/4 to full just caused the motor to puke it into the catch can.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

Funny we're both looking at the data at the same time.My T1 entry on my best quali lap is braking from 144 to 100 and dropping to 95 mid turn at 9800 RPMs. Under braking with the wet sump I am at 31psi throttled closed...1/3 the way in the turn I pick the throttle back up and bounce back to 49psi at the 9800 then up up to 60 by corner exit.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

John, it has nothing to do with you picking up the throttle. My point is, even if you didnt pick up the throttle there, the oil pump already got another gulp, psi was going up regardless. Think about it, throttle has nothing to do with oil psi, only rpm. And any pump better be putting out max psi well before 9000rpm.

Arnd possibly our failures are happening sooner because of the built/added power. More power more wear. Slowly damaging rod bearings because they are the last to get oil. And then....Kablam

And this explains another thing. Why some dont have failures and some do. Its the track! RA is know to be one of the hardest on brakes. 1,3,5,8,12. Input guys? Jake?

Are we on to something here?

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

Guys,

Check your data in turn 8 and 12. These corners are a bit more prolonged under braking. Turn one as I used to take it was a early on the power type of corner. Maybe the data on 8 and 12 will have more to back up your theory.

Lawrence -

how 'bout the sections where you really have to drop anchor? I don't know the corner numbers, but the lefthander before the Toyota bridge, and the lefthander that leads into the carousel?

John Stecher and I compared our data, and his shows the exact same kind of dip, even including the delay between throttle pickup and when oil pressure starts to increase again.

Looks like I was typing while John and Lawrence were.

-Jake

Last edited by JakeL; 07.09.09 at 12:01 AM.

So below are my two fast laps from BHF earlier this year and then the sprints in both races. All the other laps mirror these. z-axis is psi of pressure measured at the stock bike position and then RPMs is the top line and brake/acceleration G's is the other line. Might as well talk to empirical evidence so everyone knows what we're talking about and has a visual reference.

What I don't understand is if this is a sump problem why only under braking? I pull much higher G loads under cornering in the carosel and other places without the pressure missing a beat...

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

So here's a few laps of mine at HPR. Note how long it takes for the oil to return to "normal" after Turn 8 (highlighted). You come up to it approx 100-105, and go down to first. Hardest braking on the track:

Attachment 15085

Attachment 15086

Maybe there's more to it than I can see?

-J

Last edited by JakeL; 10.05.15 at 11:21 AM.

I'm probably missing something, but it sounds like the oil pick up is becoming uncovered during braking. Is there something that is making you think that isn't the cause?

Racer Russ

Palm Coast, FL

I have to look for sure but if I remember correctly, the p/u is located in rear of pan and the pan is longer than it is wide. Plus got to look at where the drain back holes are.

Ok, corner 12, same lap.

Entering at 151mph, 1 second into breaking, 125mph & 36.9 psi.

1 second more, 96.8mph & 32 psi.

.6 seconds later, boom 50 psi & 79mph.

1.5 seconds later, 70mph (slowest speed) & 56 psi (but still no throttle).

A tenth or so later I can see I pick up the gas (throttle % increases) but oil psi is already good.

Beside looking at oil psi, its crazy to realize Im on the binders for that long, it doesnt seem that way in the car.

I cant see G's under braking/accel only turning, but in older video where I have that being displayed in the video braking Gs into 12 were approx 1.6G's.

http://www.youtube.com/watch?v=wETlKnRHvm8

God I hope we're onto something.

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

Agree Russ, its just been said to be normal to see this under braking. Everyone uses the same pan for years from what I understand and it looks like a great piece, but might not be enough.

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

Bikes will routinely stand up on the front wheel during hard braking, which may not be pulling as many Gs, but I'm sure it's putting the oil pretty far forward, damn near the top of the oil reservoir.

Bikes do not generate lateral Gs though, relative to the oil pan at least.

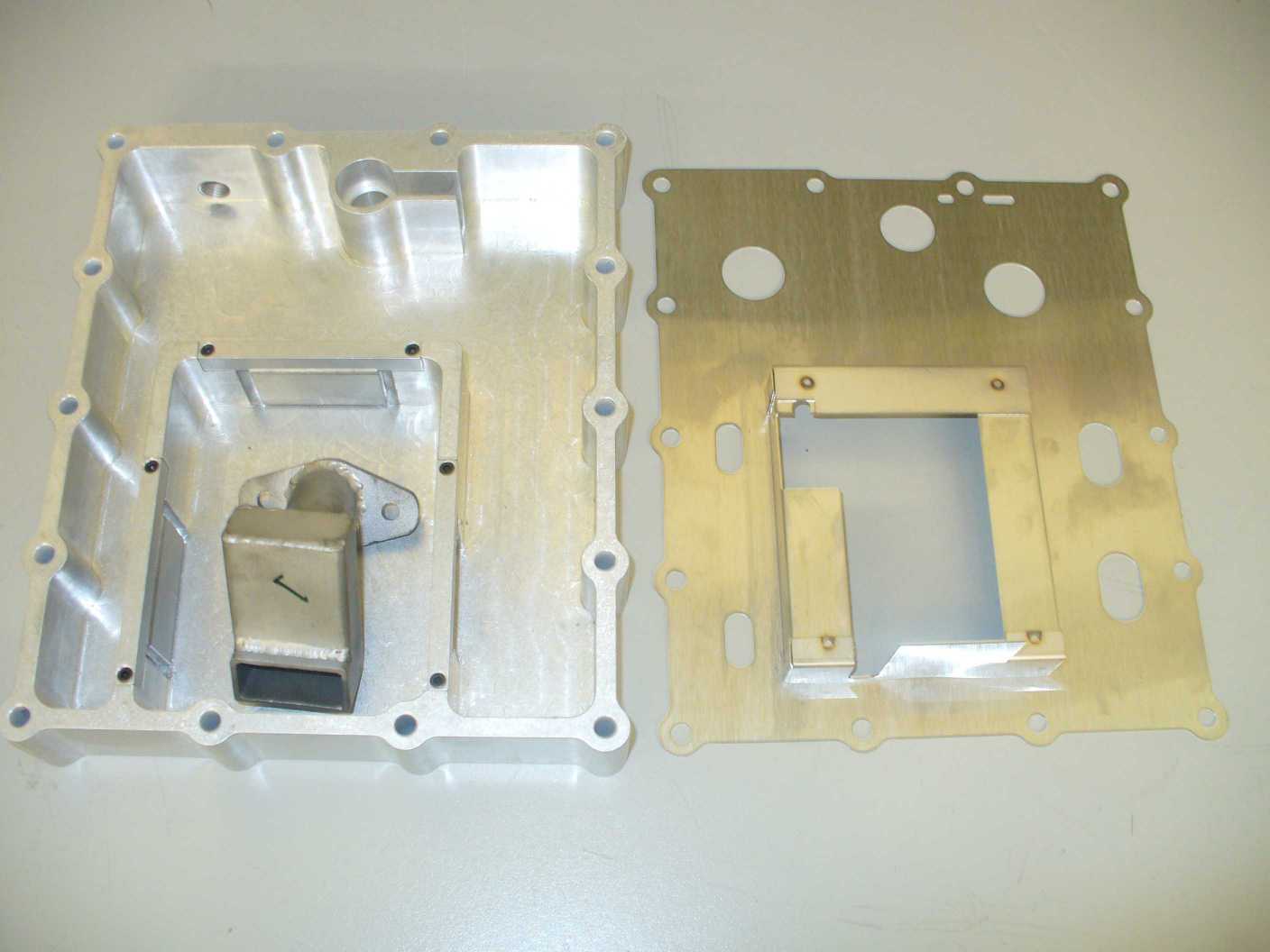

Here is a picture of the pain internals that everyone uses. Just different names stamped on the bottom.

Lawrence does your blip back up in oil pressure coincide with a downshift. I'm down 2 gears by the time I get to 1.5 seconds into braking. Just wondering with your dry sump if your spinning the motor faster after a ds than you are after initial braking.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

We're not using the same pan, but we have had our own problems as well. I haven't killed an engine yet (4 National races + tests). At the June Sprints our oil pressure problems were obvious. I've attached some screenshots of the data. The first pic is the before shot. Between the shots we did a few things: remove the accusump, change the pickup and baffle to the one in John's shot above. I had fabricated my own parts, but I had underestimated the problems with keeping oil at the pickup under braking. Things are getting much better in the second picture. At Roebling the oil pressure never dropped below 45psi.

I think that we are getting there, but I'd still love to remove the drops in pressure entirely.

Brandon -

From looking at the map of Roebling, it looks like there's not any place you have to brake very hard, except perhaps somewhat harder at whatever corner is at the top right of the map (I'm guessing that's T1?). Is that the case?

Russ -

I think that at least Lawrence and I are starting to think pretty strongly that starvation under braking is exactly what is happening, but there are sure more expert opinions out there than mine. It would be fairly diagnostic if anybody with a dry sump system posted and their logs did *not* show a similar issue. Any takers?

George - if you're still watching, any comments on the datalogs posted?

-Jake

Looking at the pickup unit and pan once again here I am wondering if its not best to have a half door for the front of the pickup (something that allows flow back in under acceleration but allows minimal seep around the sides of the door under braking (if that's where its flow out and around). Then I would say to ensure the motor gets fed under acceleration add two more feeder holes to the pickup chamber at the very back of the castings surrounding the pickup after of the flappy doors there.

I'm still baffled as to why lateral G's don't produce the same problem AND I also am baffled as to why and accusump didn't fit the problem either unless the oil coming in could never reach the pickup because of being blocked for some reason.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

the oil is not going out of the pickup box, it is being sucked out by the pump while all the oil outside the box is at the front of the motor thus no more oil to refill the box. thats when the pump sucks its air. at the end of the braking event, the oil is sloshing back and thus refills the box and pump sucks oil once again. the reason you dont see it as bad in lateral g's is because they are more sustained. braking is instant throwing the oil rapidly forward. put a bucket of water in the back of your truck and go drive. hit the brakes hard, and watch the water fly over the front of the bucket, then corner as hard as you can and watch it just kinda slosh up one side and appear to be at an angle. cornering g's just are not as harsh as braking.

Agree Jesse, thats what Im getting at, you're 100% right with your bucket example.

Now after really looking at the pan, (never really did, just accepted it as good because its what everyone ran) here are what strikes me as wrong:

1) Q: what fills the pickup box?

A: The instant we accel or turn and a door opens otherwise nothing!!

2) Why is p/u all the way toward rear of engine?

A: This is the classic thought of where to stick a fuel p/u because you're on the gas way more than braking, but isnt ideal for our situation. **same video link posted above only shows max of .45G's accel but mostly <.3G's. AND as Jesse describes we pick up the gas and turn in way smoother than jumping onto the brakes.

Thoughts on modding pan:

1) thinking of plumbing a line from relief valve dump and routing it to dump into pick up box.

2) Increasing volume of pick-up box can hold, it doesnt seem to be even close to enough. ***Has anyone tried just a pan like this one but without pick up box BUT with a lid for the entire pan?

3) turning actual pick up around 180 so its picking up from more in the center of pan.

True fix: Drysump. I'd already be running one if the damn stock pump was able to just pull oil from the tank.

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

Accusump explained and why it wont work:

it's simple, think of an AS (accusump) as a hydraulic capacitor just storing energy, oil psi. Its a tube with a piston in it. The pre-load psi is pushing the piston lets just say to the far right of the tube. Once the engine is started, oil psi anything greater than the pre-load psi starts to fill AS and pushes piston back to the left side of tube. The piston has rings to totally separate the two sides of it. Once the psi on both sides is equal it just sits in that position, approx less than 1/2 way because of the preload psi. Now as soon as psi in engine is lower than the stored psi in AS, it just pushes the oil out of it. So, in our application we dip to 30, it would open, oil is pushed back into engine at no where near the volume a pump would produce (and hopefully in right direction) and AS empties until psi is equal in AS and engine psi just like it fills. So 75 into 30 to 74/31, 73/32, 72/33.... Just take a peek at how slow an AS fills, how is it fast enough to save bearings? It is better than nothing if not using a baffled pan.

Lawrence Loshak

'13 FB & HP National Champion

'10 DSR National Champion

'06 EP National Champion

i thought that pick up picked oil up at the front of that box, not the back? also, the oil will "open"those doors itself to get in the box even if not cornering or braking. it is simple fliuid dynamics, the oil has plenty of head pressure to open those little light weight flaps.

That pickup is about 1" forward of the pickup hole/flange in the engine. I don't know that it even makes it as far forward as the middle of the pan.

I have been following these posts & of course it is extremely interesting with a ton of really valuable info.

An intersting bit of info is is how much the stock pressure pump actually flows. A GSXR600 engine flows about 40 to 50 liters a minute when at racing engine speeds depending on RPM. This is a huge amount of oil to flow & I am certain that the GSXR1000 engine flows even more.

Let's say that your oil pan holds 4 quarts of oil (about 4 liters), that is equal to about 6 seconds of oil in the pan at 40 L/minute. So if there is any reduction of oil flow back to the pan you are going to have capacity problems. I would imagine that there are MANY times where flow back to the pan is seriously restricted due to G forces etc. Anytime that flow back to the pan is restricted then the opportunity for the pressure pump to starve & pump air is much more possible. I suspect that the severe braking associated with these cars forces the oil high up in the front of the engine thus limiting the effective volume of oil in the pan and causing pump starvation under hard braking.

I have desiged a new pan for our GSXR 600cc powered F500 that I think might solve the problem with wet sump pans. I hope to have it on the track in a few weeks & I will report if it works. Hope springs eternal in the racers heart!

Thanks ... Jay Novak

Thanks ... Jay Novak

313-445-4047

On my 54th year as an SCCA member

with a special thanks to every SCCA worker (NONE OF US WOULD RACE WITHOUT THE WORKERS)

So I dont exactly buy the slosh forward a bucket theory as causing you to lose more oil out of the pickup area than prolonged G's in a turn like the carosel but fine I'll go with it. Wouldnt we to prevent that from happening need to more effectively cap the pan to keep the x quarts of oil it holds in the pan? Seems that if the pickup was in a sealed chamber thats full of oil it doesn't matter how many G's you apply to it by the fact its sealed it wont allow oil out beyond being pumped out of the pickup. Obviously you need return lines in there but that seems like a solveable problem as well.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

what you describe is a dry sump systemwhy do you not buy the difference in braking g's over sustained lateral g's? pull up your data and look at your g's you will notice that the ramp up angle of the g's under braking is much quicker then the ramp up in lateral g's now combine the quick ramp up under braking with the lateral g's on turn in and you experience a double negative, so you see what jay just described. you have all the oil up in the front outside corner of the motor and what is left in the pick up area is sucked up in less then a second. as the g's reach a sustained level and you get off brakes, reach apex, etc. you are maxed and the car starts to transition for acceleration out of the corner. the oil is now back near the pickup and pressure comes up either slightly before picking up the gas or in some cases right as you pick up gas and in extreme cases, slightly after you pick up the gas. if you look at your brake pressure graph, oil pressure graph, and g's graph all at the same time, you should be able to visualize what is happening to the oil as all the graphs move up and down. it all makes sense, that is what i did and realized the only thing that will for sure fix this problem is a proper scavenge system. the right wet sump pan design and oil level might work at most tracks, but it will still be a power loss compared to proper dry sump. remember, these cars get faster and faster and go through the corners better and better every year as new advances are made with aero etc. this problem will only get worse!

If I take a full bucked and slash it forward violently at a 45 degree angle yes crap flies out everywhere. If I slowly tilt it to the side up to a 45 degree angle for a period of ohh 14 seconds I dump out the same if not more water. 2G's consecutive in my head around a turn would cause the same issue...basically pull all the oil into one side of the pan away from the pickup. Everything is on the left hand side of the motor with just the stuff being returned to the engine coming back into the pickup but alas I see no drop in pressure. Brake while more violent moves the oil to the front of the sump in the same manner...maybe faster but at the end of the day in the same manner.

To me the problem then would be if I assume something is trapping in and returning oil correctly in the turning case what is causing the oil to either escape or not be returned correctly in the braking case.

Thats why I don't buy that braking would cause anymore drastic of an issue than turning assuming the escape and return paths of the oil are consistent in both cases.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

you are missunderstanding the bucket idea. i think this makes sense to everyone else, and the data shows it. not sure why you still want to fight it. the idea with the bucket test has nothing to do with tilting it an angle nore filling it to the top. fill it half way. hit the brakes and fluid will fly over the top before sustaining at whatever angle relative to g's, and still below the top of the bucket, the point is it goes to a larger angle if you will from the initial hit then it would with that amount of g's, but bucket is still verticle, go into corner and fluid will go to whatever angle relative to g's and hold that angle as long as g's are sustained. forget the bucket, back to your engine. it starves under braking and not in corners, that the way the cookie crumbles, argue it if you will. no need for me to try to make sense of this any longer, i am only trying to help. george is probably rolling on the ground laughing at me right nowget back to work!

We have been talking about the oil moving around in the pan under sustained longitudinal and combined longtudinal/lateral g, but is there a possibility, depending on the locations of inlet/oulets for the coolers, we are pushing it out of the pan totally? It seems we are using long lines and large coolers, much larger volumes than in a motorcycle with totally different dynamics. Are you getting different effects left to right? I don't know, I am not an engine guy, so I could be way off.

Ken

You're answer is always dry sump this dry sump that...fine thats what you sell I get it.

My point in arguing with you is force is force, math is math, 2G's in a turn over time segment A is 2G's under braking over time segment Z moving a constant weight fluid. The G's (force) applied to the fluid are going to move the fluid the same distance from a given point (pick up in this case) if they are abrupt and short lived (braking) or if they are continuous over a longer period of time (cornering). It will always uncover the pickup its just a matter of time. I'll agree with you that the velocity of the fluid moving in a direction is different for braking versus cornering but at the end of the day they both move the same distance and both should theoretically uncover the pickup. Sorry dude that's just physics so you're not arguing with me your arguing with a lot of guys smarter than me. Cause I dont really know that much.

My point all along has been trying to figure out why that the pan design obviously works in a turn for these motors, as evidence by the long drawn out full throttle turns a lot of us had run, but why doesn't it work under braking. That's what everyone is trying to figure out together.

If you take the above physical truth the only way to keep the pan full is to seal it at the top so the oil cannot spill over the edge no matter the velocity the fluid is traveling at OR you are able to replenish the fluid in one the pan at the rate its leaving the pan. To me with it happening under braking is the result of one or the other being a problem under braking and not in turns which is a design issue with the pan of baffles that can be fixed or an engine issue dealing with the return of oil to the pan which I dont know if we can fix.

I'm not trying to be an ass I'm trying to slove the problem with logic (which you say you're trying to help) not just the answer of this is what a dry sump solves for ya. There are more than a few ways to skin a cat.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

To further move the discussion along I am getting data tomorrow from a friend who runs a 07 GSXR as a race bike. I've seen his data already for G's under braking and know he pulls around 0.8-1.1G's into T1 and T8 at RA on GPS so it should be a pretty equal comparison given the drop some of us see at nearly equal G loads.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

On my 2007 Phoenix F1K.07 I have a wet sump system and an oil pan that was designed with baffles inside the pan to keep the oil from sloshing from one side to the other due to the G forces in turns. I fill the engine case up to the oil window when the engine is runnning. Even if the oil is above the oil window I don't worry about it as George Dean has told me not to worry. If there is excess oil in the engine case, it will ultimately be puked out into the overflow. My 2007 GSXR takes 4 3/4 quarts to get just above the oil window when the engine is running. George Dean suggests a tiny bubble just below the window when running and heated up. To this date I have had no problems with reduced oil pressure. Engine has over 1200 miles and nothing has been done to the engine to refresh it as of yet. I use Amsoil Motorcycle oil and change the oil and Wix brand oil filters religously after 2 weekends or 4 events. I carefully look for debris in the oil and have not recorded any major metal particles in the oil when drained. I use a magnetic oil plug to catch any metal particles before the oil is drained. I also make sure that the engine is started 10 minutes before any track time, either practice, quailfy or race to a temp of 180-190 degrees. Then the car is shut off until I enter the grid and track. I was told that pre-heating the engine and oil reduces stress on the internal engine components especially rod ends and bearings before any stress is placed on the engine at high RPMs. So far proper oil maintainence, proper oil levels, and pre heating the engine was not resulted in any recorded engine failures or problems to this date.

These are simple things to do for engine maintainence and prevention. My rev limiter is set for 11,500 RPMs, as I told there is HP reduction after 12,000 RPMs anyway. No need to run the RPMs up to 13,000 as there seems to be no extra HP recorded at these levels and only places undue stress on vital engine components.

If your running a wet sump pan with NO baffles, I highly recommend that you contact George Dean Racing Engines and place an order for this type of oil pan. It may help save an engine failure.

I am NOT a technical engine expert at all. My expert is Dustin Wright at Phoenix Race Works and George Dean who had my engine originally. These are simple steps that have saved my engine from burning and breaking up so far. My goals is to continue this plan and get 5000 miles on the engine before any refreshening is needed. When that time comes and takes place the engine will be removed, sent to George Dean and reinstalled by Phoenix Race Works who built the car originally. 5000 miles of running the car should equate to 5 to 6 years on the engine with my present race schedule of events annually. The car was delivered in Sept 2007. This may be optimistic but may also be realistic also. Time will tell. There has to be consequences to the engines when running these motors constantly at RPMs in excess of 12,000. 13,000 RPMs has to be at the extreme limits and create maximum stress on vital engine components.

Just my 2 cents worth of inexperienced knowledge of F1000 engines.

Last edited by Richard Dziak; 07.10.09 at 9:29 AM.

Richard Dziak

Las Cruces, New Mexico

Former Phoenix F1K-07 F1000 #77 owner/driver

website: http://www.formularacingltd.com

email: sonewmexico@gmail.com

my answere is dry sump as in my experiences, on multiple differnet types of race cars has always been dry sump. this motorcycle engine crowd is the only crowd i have ever seen that insists on trying to make a wetsump work. i cant get over how many engines have to blow before everyone decides it just doesnt work. in all the conversations i have had with multiple people, i have heard more crazy excuses and theories then you could imagine. i guss it comes down to its all over thought. i have been dealing with motorcycle power for 5-6 years now and have been personally involved in trying to make wetsump work. i have said above it can probably be made to work under the right conditions, with the right driver, but even then, as i have proven on a dyno standing still, it is always at a loss for power, go into a corner which can not be tested and it is believed and probably tested by those with more resources then me that more power is lost, that is why most professional race cars are dry sumped. that is why i believe in it strongly and why i started building them for motorcycle engines in the first place as stated multiple times above. when we switched to dry sumps in the west cars, all problems went away. period. now as far as making wetsumped engines live, george points out that mark made his gsxr live all last season no problem. i was at a race a few weeks ago where mark was running the pheonix, and he noticed something was wrong so george checked it out and discovered a valve keeper was lodged about to come undone, george pulled it apart real quick in car, replaced a valve and sent mark back out for the race. hes good, he is one with whatever car he runs! so to recap, my main focus on dry sump, is it is the only thing, currently, that can solve the pressure dips, and as a bonus, it restores lost power. not the only way, but i gauantee, it will save most of you money in the long run. this is about the 5th or 6th thread i have seen on trying to make wetsump work. oh and just so you know, i would have to sell at least 100 dry sumps a year to make any kind of living off of them. i built them to service a direct need, and offer them to you guys to offer a well built system as an option for you to use. i am not arguing against anything, just sharing my studies over the last 6 years and what i found to be the solution.

so richard, to clarify, you have a baffled wet sump system like the one everyone else runs, correct? it says dry sump with baffled pan, or are you saying you have, and have run both baffled wet sump and dry sump system? it sounds like you are one that wet sump works for, but as stated by lawrence and jake earlier in this thread, we are really looking at the guys that are running as hard as possible and feel that running the engine stressed is necassary to accomplish things like track records and victories at june sprints, arrc, and run-offs etc. i used mj as an example and after hangin around his pits in the f1000, i will say he runs conservative, and fast, and does not seem to blow engines. i guess more then one way to skin a cat.

This is a very interesting thread.

I don't have a wet sump, or a GSXR, and certainly not an engine expert, but I think Jay has nailed it, or at least come up with a very plausible explanation.

It seems very possible that the baffle pan, flaps etc. are well designed, but there is simply not enough oil going into the pick up area under certain circumstances. It's easy to imagine the oil being "pressed" into places briefly, preventing normal drainage downward into the pan. As Jay and others have pointed out, it would not take long for the pump to suck up the entire volume of the pick up box.

I don't want to start a dry sump vs. wet sump argument, but the dry sump probably would never have this problem (assuming the scavenge pump is not starved for oil for a VERY long time, and assuming the remote oil tank has decent volume, etc.).

I also think the idea of routing oil from the bypass valve into the pick up container is a good idea and could help in your situation. Certainly would not hurt.

Lastly, I'll be surprised if data from a motorcycle racer will shed much light on this race car problem. Too many differences. Maybe side car racers' data would be better? :-)

Racer Russ

Palm Coast, FL

I'm pretty sure Richard's is a wet sump since he is describing that oil fill method.

And I decided to spend the money on a dry sump almost three years ago when I bought my 06 R1 Yamaha for the car I was about to build. Seems to work well so far. The dry sump tank I bought from Stonebridge is the most beautifully crafted and baffled tank I've ever seen. It is cylindrical and barely fits inside the rear drive box.

Scavenge line from the engine is AN10, about 2.5 feet long which connects to a 6" long oil screen. Oil screen is connected to an oil to water heat exchanger made by Marston Aeronautics in the UK (came off a Lola Indycar). From there, it runs through another AN10 line, about 2 feet long to the oil tank top.

Oil feed from the tank to the pump (which is inside the engine in place of the usual water pump) starts with an at AN10 line about 1 foot long then goes through an AN12 line for another foot to the pump fitting. I also retained the normal Yamaha water to oil heat exchanger attached to the engine.

Water cooling is by electric booster pump. From engine to right radiator, through Marston heat exchanger, through left radiator, through pump, to engine with another bypass going through the Yamaha 2nd heat exchanger.

Air cooling input through two sidepanel ducts above the sidepods deflecting air toward the headers. Air cooling exhaust through the engine cover rear in three locations - way back (where a sticker says "Save the tatas" - my wife had breast cancer) and over both rear shock cannisters.

Not running data, not enough money yet, water temp stays put at 171F. No idea of oil temp or pressure. Seems to be working well so far. Data system is planned for winter. At first run, I filled oil tank to 3/4 full and let system chuck out what it did not want, which was about 1/2 quart. About 6.5 quarts in this system.

I have a wet sump system...you guys are correct. Sorry for any confusion on dry vs. wet. One word can make a major difference.

Richard Dziak

Las Cruces, New Mexico

Former Phoenix F1K-07 F1000 #77 owner/driver

website: http://www.formularacingltd.com

email: sonewmexico@gmail.com

So I think we have all defined the problem as we with wet sumps have a data validated oiling problem under braking with oil pressure dropping into the 25-30psi range*. (I really wish more people would post some screen shots of their data beyond Jake, Brandon and myself.)

If it is a pickup problem I guess I am curious why we can't just build a two headed pickup and extend out the current chamber up to the OP relief valve area that capturing oil for the engine from both ends of the sump covering then acceleration and deceleration. Seems like a simple change in design and we could test it very easy. If someone sent me a modified pan I would test it in August or I am sure Jake would test it as well. Who builds the current wet sump pans and can we make it happen? If that doesn't fix the problem then the problem exists with oil returning to the pan**

*The 25-30psi range being an issue with keeping bearings happy is another debatable point as I talked to a couple different AMA teams this morning cold calling them to ask questions. One called me back and I talked to their main engine builder about the problem. He said very directly that 30psi dips in oil pressure as long as it is not for a prolonged time (defined by him as less than 4-5 seconds) will not effect bearing life. Bearing failure is due to large amounts of air in the oil stream characterized by dips to 0psi of OP, 0-30 psi OP for prolonged periods, or material in the oil from clutch, metal shavings, or other wearable part causing non-lubricated spots.

**I also asked him about baffles and plates to contain the oil in the pan. He said that the reason the bikes don't have baffles is that their movement is in all three axis. So if they baffled the pan oil draining back out of the engine would in most cases not progress back down into the pan until the bike was in a set geometry. Which I take to mean means the oil would roll around on the baffle versus falling though the holes back into the pan...is this possibly what's happening under braking for us? Oil is moving forward on top of the baffle with no way to drain down into the pan and thus not refilling the pickup chamber?

Beyond that Jesse you are right there are benefits to a dry sump for hp and other things outside of this oiling discussion and there is value there I don't doubt it and you and George have proved it out. My biggest concern with the dry sump route in this class and xSR is that we arent in FC or FF or Atlantic where we have the same engines for 10-20 years and you can buy a dry sump and use it forever basically. Motors change in these classes every 2-3 years which typically requires a totally new dry sump or oil pan setup. I'd like to find the cheapest alternative for folks to be able to upgrade and get out on track...then if people want the extra hp or benefits of a dry sump they can add pay the extra dollars for one and get the benefit. I would like it as a addition not a requirement to keep these motors alive if we can figure it out. You're doing cool stuff...I'm just trying to find answers on both sides.

John Stecher - Rochester Minnesota

http://twitter.com/johnstecher - Follow me on Twitter

http://www.trackpedia.net/blogs/john/ - My Blog

http://www.trackpedia.com - The world's premier race track reference

i have had this idea for a hybrid system for over a year now, and george didnt think it was a very good idea, but i will throw it out there, because i still think it would work. i can put a small scavenge section in the pan that would simply pickup in the front of the pan and put oil into the pickup box so under hard braking, it is puting oil back in the box. i call it a hybrid wet/dry sump using the pan as the resevoir. the possible down sides is oil aeration, but i would have the exit tube go up and then bend to point down at the back of the box about 3" off the bottom so it squirts from the top of the oil level so if and when it blows air, it is not near the engine pickup. the other is the pump would displace valuable oil volume and the gear to drive it would be in the oil robbing power, and aerating the oil a bit. the other option is a small external pump and electric water pump, but i know everyone wants away from that.

i also have a wetsump design that i think would work better. i have not released it as i didnt figure it was worth it since all the wetsump guys prior to now were very happy with the current offering. figured it would be an even tougher market to break into then this dry sump business has been.

i am trying to get my dry sump down in cost, so it is more affordable. i am also trying to simplify the system so it is easy to install and adds minimal weight gain. if i accomplish this, i really would not see the upside to screwing with wet sump. i still believe the best answer is a dual scavenge dry sump. and as soon as i get 100 orders for the year i will be rich!!!!!

currently most people blow about 3-5 engines a year and the point is one engine pays for the dry sump, so the 2-3 year engine thing would still save you money! an atlantic rebuild costs as much as 4 of these engines! so 1 engine and 1 dry sump is WAY cheaper then any of the above. you can not do 2 pickups off 1 pump, if one sucks air, the other would lose its suction as well. its like breaking your straw at mcdonalds, you get air instead of soda! the alternative would be my hybrid setup. also, the gsxr has been the same since 2001, and the 09 doesnt seem to be any better, so no need to worry for a while at least. also there will always be guys running the older stuff, so there will be a market to sell your old engine and dry sump when you go to a new setup.

There are currently 1 users browsing this thread. (0 members and 1 guests)