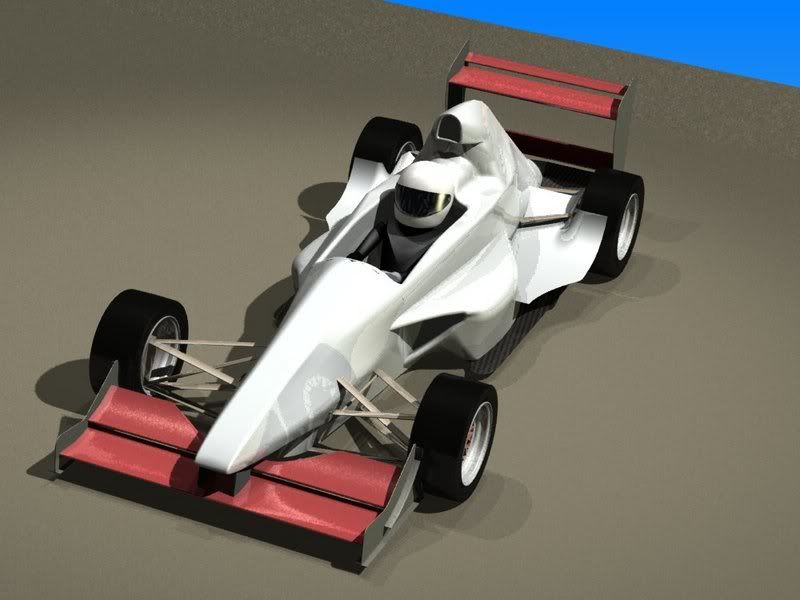

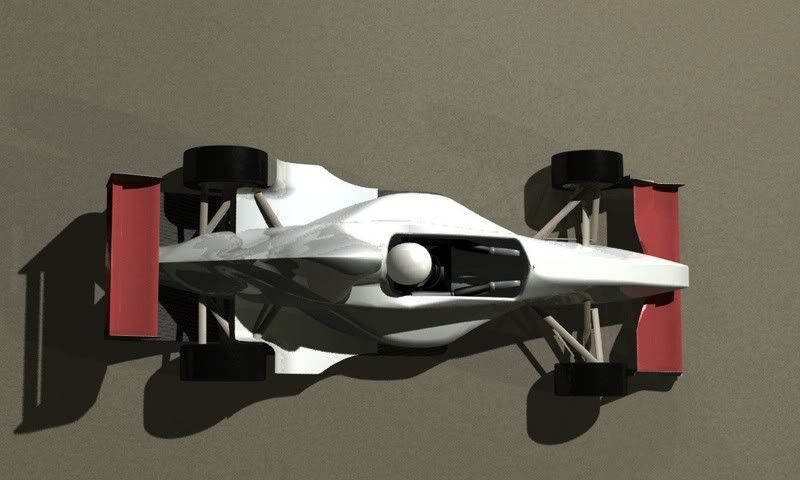

We are pleased to release a few images of the design for the new Phoenix F1K-07 Formula 1000 car. We'll be releasing more information regarding the complete car specifications in the next week, but here's a few standard features we think will differentiate us from some other offerings and make our car a great value for this exciting new class:

By including these features as standard on the F1k-07 we feel we're giving our customers the tools they need to have a competitive package right from the start. As I don't want to cross the line and make this a retail post I'll stop now, but I have inquired about becoming a sponsor of this site....so look for our "official" ads soon.

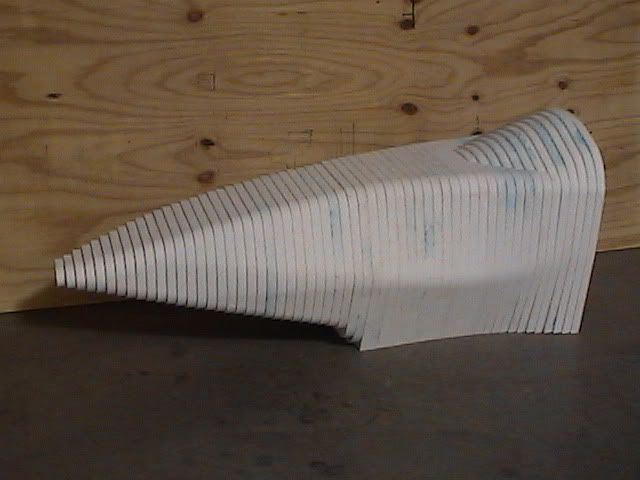

- Race-proven wing design from Pennon Composites. Front wings are the Aero-Avant design with single-element main plane and secondary elements for maximum adjustability. Rear assembly consists of a single plane lower element and a high-downforce, adjustable, dual-element upper assembly.

- Penske 8100 double-adjustable shocks custom-valved by Chris Harrison of Harrison Auto Dynamics of Phoenix. Option available for 8760, triple-adjustable units.

- Adjustable Anti-Roll Bar for the front and rear of the car. Option available for cockpit adjustment.

Matt Conrad

Phoenix Race Cars, Inc.

Reply With Quote

Reply With Quote